News

- Excellent Performance Automatic Mixer Blender1. Application: This machine will improve production efficiency and decrease work intensity in mixing process. 2. Main characteristic: 1.Touch screen control 2. First time use the patent technology into the auto pre-mixer 3. Double direction mixing 4. Adjustable position during mixing 5. Double direction crushing 6. Collecting system while stopping 7. Easy to clean and change color 3. Main Technical Parameter: Model Volume (L) Capacity (kg/tank) Mixing motor (kw) Rotary motor (kw) Crushing motor (kw) (kw)*2 Mixing time (min) Mixing speed (rpm) Overall dimension (mm) APM-300 300 100~200 9~11 0.55 - 0.25 5~10 88~130 1755*1072*2315 APM-600 600 300~400 18.5~22 0.75 3.0 0.37 5~10 63~95 2550*1300*2900 APM-1000 1000 500~600 26~32 1.1 3.0 0.75 5~10 45~65 APM-1000 1000 500~600 26~32 1.5 3.0 0.75 5~10 45~65 4. Machine Pic: 5. Workshop View: We make powder coating machinery(blender for powder coating, twin screw extrusion machine, powder coating cooling conveyor, grinding equipment) part in our own factory to control the quality of the machine parts to make sure the machine's quality. 6. Working Process 7. Our Advantage & Service: -Technical Support Online Service Provided According to customer's requirement, we provide layout (plant designer), excellent mechanical engineer, excellent electrician, etc. -On-site Training Service Provided In customer factory, we provide all kinds of training, including installation, commissioning -Long-term Maintenance Provided In the area of maintenance, we offer needs-oriented and standardized maintenance packages, such as the overhaul of components, gearboxes, in order to guarantee the safe and economic operation of plant and machinery. -Spare Parts Replacement and Repair Service Provided Providing spare parts for all kinds of powder coating processing equipment in long-term. And can provide tailored made spare parts according to customers' requirements. Ensure advanced craft, good material and high precision. -Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply all powder coating raw materials( polyester resin, epoxy resin, barium sulfate, gloss agent and so on) in the formulation. 8. Coating Show We sincerely welcome customers from all over the world come to visit and negotiation with us!

2024 01/20

- Small Capacity Lab Grinding EquipmentFactory Price Lab Grinding Equipment 1.Application: Lab mill can test powder coating formulation result accurately. 2.Main Characteristic: 1.Main technical parameter match the production line grinding system 2.Pin disk driven with high speed electromotor directly 3.High accurate 4.Mill chamber is driven by high speed motor directly with adjustable rotary speed 5. Easy to clean and change color 3.Main Technical Parameter: Model Main motor power(kw) Capacity(kg/h) Pin disk speed(rpm) Classifier power(kw) Classifier speed(rpm) Fan power(kw) Fan flow rate(m3/m) Overall dimension(mm) ACM-02 1.5 5~10 10000~14000 0.37 500~3000 2.2 3.0 1100*1000*1800 4.Machine Picture: 5.Workshop View: We make powder coating machinery( powder coating mixer, powder Coating Extruder ,Powder Coating Cooling Conveyor, ACM Mill for Powder Coating) part in our own factory to control the quality of the machine parts to make sure the machine's quality. 6.Working Processing: 7.Our Advantage & Service: -Technical Support Online Service Provided According to customer's requirement, we provide layout (plant designer), excellent mechanical engineer, excellent electrician, etc. -On-site Training Service Provided In customer factory, we provide all kinds of training, including installation, commissioning -Long-term Maintenance Provided In the area of maintenance, we offer needs-oriented and standardized maintenance packages, such as the overhaul of components, gearboxes, in order to guarantee the safe and economic operation of plant and machinery. -Spare Parts Replacement and Repair Service Provided Providing spare parts for all kinds of powder coating processing equipment in long-term. And can provide tailored made spare parts according to customers' requirements. Ensure advanced craft, good material and high precision. Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. 8.Coating Show: We attend the coating shows abroad, like Chinacoats, Eurpean Coating Show, PaintIndia, Middle East Coatings Show, Turkcoat and PaintIstanbul.

2024 01/13

- Hot Sale Barium Sulfate FillerHigh whiteness, strong thermal stability, good surface leveling, high fullness barium sulfate can be used as filler for Rubber filed, Product Specification: Appearance: White Powder Barium Sulfate (%) ≥ 92% Whiteness: ≥85% Glossiness:90 Particle size D97:3000mesh Particle size D50:9000mesh Gloss:Satisfactory Quantity per one container:24tons Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in producing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 12/27

- Liquid Paint Natural Barium SulfateBarium Sulphate can be used as filler for paint, High whiteness, strong thermal stability, good surface leveling, high fullness, and less prone to yellowing in white powder coatings. Product Specification: Appearance: White Powder Barium Sulfate (%) ≥ 85% Whiteness: ≥84% Glossiness:88 Particle size D97:2500mesh Particle size D50:8000mesh Gloss:Satisfactory Quantity per one container:24tons Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in producing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 12/18

- BaSO4 filler for Rubber MaterialsBarium Sulphate can be used as filler for rubber filed, High whiteness, good surface leveling, high fullness, and less prone to yellowing in white powder coatings. Product Specification: Appearance: White Powder Barium Sulfate (%) ≥ 92% Whiteness: ≥85% Glossiness:90 Particle size D97:3000mesh Particle size D50:9000mesh Gloss:Satisfactory Quantity per one container:24tons Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in producing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 12/09

- Barium Sulfate for Liquid ProductHot selling product Barium Sulfate can be used as filler for liquid paint, High whiteness, strong thermal stability, good surface leveling, high fullness. Product Specification: Appearance: White Powder Barium Sulfate (%) ≥ 85% Whiteness: ≥84% Glossiness:88 Particle size D97:2500mesh Particle size D50:8000mesh Gloss:Satisfactory Quantity per one container:24tons Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in producing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 12/07

- Barium Sulfate for Liquid PaintHot selling product Barium Sulfate can be used as filler for liquid paint, High whiteness, strong thermal stability, good surface leveling, high fullness. Product Specification: Appearance: White Powder Barium Sulfate (%) ≥ 85% Whiteness: ≥84% Glossiness:88 Particle size D97:2500mesh Particle size D50:8000mesh Gloss:Satisfactory Quantity per one container:24tons Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in producing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 12/04

- Precipitated Barium Sulfate Baso4 for PlasticsPowder Coating Application Baso4 used in all kinds of transparent enhancement masterbatch, color masterbatch,coating(powder coating,car paint,wood paint, exterior wall paint, anticorrosive paint),electronic ink, printing ink,some advanced plastic( PP,ABS,PE,PS,PA,PBT,PET and car plastic)rubber, paper and cosmetics. Barium sulfate is used in coating,painting,plastic,rubber. Product Specification: Appearance White powder Barium Sulfate (%) ≥ 98% Whiteness: ≥97±0.5 Total Iron (%) ≤0.006 Brightness (%) >97.0 Sulfide Content (%) <0.005 Oil Absorption (g oil/100g) ≤15±2 Moisture (%) ≤0.15 Dispensability Good Residual (g/kg) 0 Fake (g/cm³) 2.2±0.2 sp.m/g 27000±500 PH value 7.5±1 Real (g.cm³) 4.4 Average particle size (µm) ≤ 0.8±0.1 Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 11/29

- Polyester Resin Plant (TGIC System 93: 7)Application: Mainly used as Curing Agent for pure polyester powder coating, also used to produce electrical insulation materials, laminated sheeting, printed circuits, tools, adhesives,, stabilizer for plastic, etc. It has good weather resistance due to its very stable chemical properties. It provides good reactivity because of its free functional epoxide groups when get mixed with polyester resins. No VOC will be emission during curing process. Specification: Appearance White granule or powder Epoxy Equivalent (g/mol) <110 Chlorine(%) <1.5 Melting Range (℃) 90-125 Viscosity(at 120±1) ℃ (mPa·s) <100 Volatile Matter (%) < 1.0 Epichlorohydrin(ppm) <50 Recommend Formulation: Polyester Resin 55.8 (93:7) TGIC 4.2 Titanium Dioxide 40.0 Leveling Agent(100% active) 0.5 Benzoin 0.3 Production Picture Our Exhibition Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 11/18

- Precipitated Barium Sulfate Baso4Precipitated Barite Powder Pigment Barium Sulfate Powder Coating Application Baso4 used in all kinds of transparent enhancement masterbatch, color masterbatch,coating(powder coating,car paint,wood paint, exterior wall paint, anticorrosive paint),electronic ink, printing ink,some advanced plastic( PP,ABS,PE,PS,PA,PBT,PET and car plastic)rubber, paper and cosmetics. Barium sulfate is used in coating,painting,plastic,rubber. Product Specification: Appearance White powder Barium Sulfate (%) ≥ 98% Whiteness: ≥97±0.5 Total Iron (%) ≤0.006 Brightness (%) >97.0 Sulfide Content (%) <0.005 Oil Absorption (g oil/100g) ≤15±2 Moisture (%) ≤0.15 Dispensability Good Residual (g/kg) 0 Fake (g/cm³) 2.2±0.2 sp.m/g 27000±500 PH value 7.5±1 Real (g.cm³) 4.4 Average particle size (µm) ≤ 0.8±0.1 Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 11/11

- Natural Barium Sulphate Use for Decorative PaintingYuanli Brand Barium Sulphate can be used as filler for paint, printing ink, rubber, plastic, insulating tape, surface paint agent for photo paper and copper plate. Sizing agent for textile. Besides this materials,we also have Benzoin,Flow agent,Polyester resin,Epoxy and powder coating machinery,mill,extruder and cooling conveyor. Product Specification: Appearance: White Powder Barium Sulfate (%) ≥ 81.6% Whiteness: ≥81.6% Glossiness:76 Particle size D97:14.56 Particle size D50:3.99 Gloss:Satisfactory Quantity per one container:24tons Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 11/08

- High Gloss Leveling Agent for Powder CoatingApplication: Our brand flow agent is a general purpose levelling agent. It can be used in pure epoxy, hybrid, pure polyester (TGIC/HAA), polyurethane systems and other kinds of thermosetting powder coating systems. Specification: Appearance: Visual inspection White powder with free flowing Activity Content : GB7531-2008 ≥65% Solid Content(%): GB/T1725-2008 ≥99.0 Package, storage and other matters need attention: 1. Store in a cool and dry place to avoid contacting other chemical products. Seal tightly after using. As this product is irritant to respiratory tract, please wear dustproof mask and glove when operating. 2. Package: 25kgs/polyethylene-lined kraft paper-plastic compound bag. 3. Validity will be 1 year under normal temperature Recommend Formulation: Epoxy Resin: 640gr Polyester Resin; 640 gr Flow agent: 20 gr Leveling agent: 45 gr TiO2 : 500 gr Benzoin:10 gr BaSO4 :300 gr Production Picture Our Exhibition Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 11/06

- Industrial Grade White Pigment TiO2Application: Products quality are very close to international advanced chloride process TiO2 products, having extreme whiteness and gloss, blue undertone, superfine particle size & narrow sizeabsorbing capacity, outstanding weatherability and chalk resistance, excellent hiding power. Recommend Formulation: Polyester Resin:600g TGIC:46g Flow Agent:8g Benzoin:5g TiO2 :350g Specifications Appearance :White powder Specific gravity: 4.1 g/cm 3 Surface treatment:Dense alumina, zirconia + organic TiO2 content %: ≥94.0 Rutile content %: ≥98.0 Matter volatile at 105ºC %: ≤0.5 Matter soluble in water % :≤0.5 Residue on sieve 45µm % :≤0.01 PH of aqueous suspension :6.5-8.0 Brightness % :≥ 97.2 Oil absorption g/100g :≤19.5 Tinting strength, Reynolds number: ≥1920 Production Picture Our Exhibition Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 10/25

- PV88 Flowing Agent for Powder CoatingOur brand flowing agent is equivalent to worleee resin flow PV88 can be applicable to any powder coating systems such as EP.PES/EP hybrid, PES/TGIC.PES/Primid and PU etc. Specification: Appearance: Visual inspection White powder with free flowing Activity Content : GB7531-2008 ≥65% Solid Content(%): GB/T1725-2008 ≥99.0 Package, storage and other matters need attention: 1. Store in a cool and dry place to avoid contacting other chemical products. Seal tightly after using. As this product is irritant to respiratory tract, please wear dustproof mask and glove when operating. 2. Package: 25kgs/polyethylene-lined kraft paper-plastic compound bag. 3. Validity will be 1 year under normal temperature Recommend Formulation: Epoxy Resin: 640gr Polyester Resin; 640 gr Flow agent: 20 gr Leveling agent: 45 gr TiO2 : 500 gr Benzoin:10 gr BaSO4 :300 gr Production Picture Our Exhibition Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 10/20

- Benzoin for Powder CoatingBenzoin is to eliminate the bubbles in the melting powder coating, i.e. eliminate the key factor resulting in film pinhole.It can be applied in all categories of powder coating.Application method: mix with other ingredients directly before extrusion.The recommended dosage is about 0.3~0.8% calculated on total formulation weight. The precise amount shall be based on the lab test.Its dosage should be properly controlled to obtain suitable film, as superfluous Benzoin may cause yellowing phenomenon. Specification: Appearance : white or light yellow crystal Melting range: 132~137℃ Boiling point:194℃ Extrusion & Curing conditions: Temperature 110℃~115℃ Thickness of film (um) 60~80 Curing conditions 185℃/15min Recommend Formulation: Epoxy Resin: 640gr Polyester Resin; 640 gr Flow agent: 20 gr Leveling agent: 45 gr TiO2 : 500 gr Benzoin:10 gr BaSO4 :300 gr Production Picture Our Exhibition Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 10/18

- Barium Sulfate Precipitated (BaSO4)98%minBarium sulfate is a white crystalline solid that is commonly used as a contrast agent in medical imaging procedures, such as X-rays and CT scans. It is used to enhance the visibility of certain organs, blood vessels, and tissues in the body during these procedures. Barium sulfate is insoluble in water and is not absorbed by the body, making it safe for use in diagnostic tests. It is also used in the production of pigments, paints, paper coatings, and plastics. Product Specification: Appearance White powder Barium Sulfate (%) ≥ 98% Whiteness: ≥97±0.5 Total Iron (%) ≤0.006 Brightness (%) >97.0 Sulfide Content (%) <0.005 Oil Absorption (g oil/100g) ≤15±2 Moisture (%) ≤0.15 Dispensability Good Residual (g/kg) 0 Fake (g/cm³) 2.2±0.2 sp.m/g 27000±500 PH value 7.5±1 Real (g.cm³) 4.4 Average particle size (µm) ≤ 0.8±0.1 Product Picture Our Exibition: Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. We also have more than 30 years experience in pruducing powder coating mixer, extruder machine, cooling belt and grinding mill system.

2023 10/16

- Outdoor Anti-yellowing Polyester Resin for Powder CoatingThis kind of polyester resin with TGIC in 93/7 for exterior environment polyester powder coatings.It is a kind of saturated polyester resin. Besides this materials,we also have Benzoin,Flow agent,Precipitated barium sulfate,Epoxy and powder coating machinery,mill,extruder and cooling conveyor. Product Properties -High gloss; -Good flow; -Good mechanical properties; -Perfect anti-yellowing; -Good storage stability. Specifications Appearance: Chip solid Color(50% DMF): Max. 3 Acid Value (mgKOH/g): 28-34 ICI Viscosity (200ºC) Po.: 40-50 Softening Point(ball)ºC: 100-120 Tg(ºC): Appr. 67 Starting Formulation Yuanli NEWPOL-01903: 600g TGIC:46g Tio2:350g Flow Agent:8g Benzoin:5g Film Properties Thickness:60+_10 Gloss (60)%: Min 90. Adhesion(2mm):0-1 Bending(mm):Max 4 Impact(kgcm):50 Hardness(pencil)H:1H Product Picture Our Exhibition

2023 10/12

- Double Direction Crushing Powder Coating MixerDouble Direction Crushing Powder Coating Mixer 1. Application: This machine will improve production efficiency and decrease work intensity in mixing process. 2. Main characteristic: 1.Touch screen control 2. First time use the patent technology into the auto pre-mixer 3. Double direction mixing 4. Adjustable position during mixing 5. Double direction crushing 6. Collecting system while stopping 7. Easy to clean and change color 3. Main Technical Parameter: Model Volume (L) Capacity (kg/tank) Mixing motor (kw) Rotary motor (kw) Crushing motor (kw) (kw)*2 Mixing time (min) Mixing speed (rpm) Overall dimension (mm) APM-300 300 100~200 9~11 0.55 - 0.25 5~10 88~130 1755*1072*2315 APM-600 600 300~400 18.5~22 0.75 3.0 0.37 5~10 63~95 2550*1300*2900 APM-1000 1000 500~600 26~32 1.1 3.0 0.75 5~10 45~65 APM-1000 1000 500~600 26~32 1.5 3.0 0.75 5~10 45~65 4. Machine Pic: 5. Workshop View: We make powder coating machinery(blender for powder coating, twin screw extrusion machine, powder coating cooling conveyor, grinding equipment) part in our own factory to control the quality of the machine parts to make sure the machine's quality. 6. Working Process 7. Our Advantage & Service: -Technical Support Online Service Provided According to customer's requirement, we provide layout (plant designer), excellent mechanical engineer, excellent electrician, etc. -On-site Training Service Provided In customer factory, we provide all kinds of training, including installation, commissioning -Long-term Maintenance Provided In the area of maintenance, we offer needs-oriented and standardized maintenance packages, such as the overhaul of components, gearboxes, in order to guarantee the safe and economic operation of plant and machinery. -Spare Parts Replacement and Repair Service Provided Providing spare parts for all kinds of powder coating processing equipment in long-term. And can provide tailored made spare parts according to customers' requirements. Ensure advanced craft, good material and high precision. -Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply all powder coating raw materials( polyester resin, epoxy resin, barium sulfate, gloss agent and so on) in the formulation. 8. Coating Show We sincerely welcome customers from all over the world come to visit and negotiation with us!

2023 10/07

- High Efficiency ACM Mill for Powder CoatingHigh Efficiency ACM Mill for Powder Coating 1.Application: ACM mill is designed with speed milling and air classifying and in the function of grnding, classfying, cyclone seperation, sieving and extra fine powder collecting. It can be used to grind powder coatings into dust. 2.Main Characteristic: 1. Openable main grinding case for easy access to inside parts for cleaning and maintenance 2. Openable top cap by means of electromotor for easy access to internal parts of cleaning 3. Perfect particle size distribution 4. All parts to be in contact with powder coating made from stainless steel 5. Equipped with famous brand electrical parts 6. Equipped with tracking suspended sieve 7. Classifier never stick with powder 8. Two kinds of pulse time setting 3.Main Technical Parameter: Model ACM-10 ACM-15 ACM-20/25 ACM-30 ACM-35 ACM-40/50 ACM-60 Main motor power(kw) 7.5 11 15 22 22 30/37 45 Pin disk speed(rpm) 7000 6500 6000/4500 4500 4000 4000 2900 Classifier motor power(kw) 1.1 2.2 3 3 4 4 4 Classifier speed(kw) 0~2800 0~2800 0~2800 0~2800 0~2800 0~2800 0~2800 Feeding motor power(kw) 0.55 0.55 0.55 0.55 0.75 0.75 0.75 Grinder cover motor power(kw) 0.18 0.18 0.18 0.25 0.25 Discharge motor power(kw) 0.37 0.37 0.37 0.37 0.37 0.37 0.37 Rotary sieve motor power(kw) 1.5 1.5 1.5 1.5 1.5 1.5 1.5 Blower motor power(kw) 7.5 11 15/22 22 30 30/37 45 Blower flow rate(m3/min) 20 30 40/70 70 76 80 Seperating efficiency ≥98% ≥98% ≥98% ≥98% ≥98% ≥98% ≥98% Particle size MESH 120~350 120~350 120~350 120~350 120~350 120~350 120~350 Capacity(kg/h) 100~150 150~200 200~300/300~400 400~500 500~600 600~800 800~1000 4.Machine Picture: 5.Workshop View: We make powder coating machinery( powder coating mixer, powder Coating Extruder ,Powder Coating Cooling Conveyor, ACM Mill for Powder Coating) part in our own factory to control the quality of the machine parts to make sure the machine's quality. 6.Working Processing: 7.Our Advantage & Service: -Technical Support Online Service Provided According to customer's requirement, we provide layout (plant designer), excellent mechanical engineer, excellent electrician, etc. -On-site Training Service Provided In customer factory, we provide all kinds of training, including installation, commissioning -Long-term Maintenance Provided In the area of maintenance, we offer needs-oriented and standardized maintenance packages, such as the overhaul of components, gearboxes, in order to guarantee the safe and economic operation of plant and machinery. -Spare Parts Replacement and Repair Service Provided Providing spare parts for all kinds of powder coating processing equipment in long-term. And can provide tailored made spare parts according to customers' requirements. Ensure advanced craft, good material and high precision. Formulation Provided (our advantage): Some customers are worried their final products if can get best result, we have our own formulator (Engineer for powder coating formulation) who is testing and updating the formulation according to customer requirement all the time. And have very good experience for the formulation to support customer to make different effect powder coatings. We can supply customer all raw materials in the formulation, including polyester resin, epoxy resin, barium sulfate and so on. 8.Coating Show: We attend the coating shows abroad, like Chinacoats, Eurpean Coating Show, PaintIndia, Middle East Coatings Show, Turkcoat and PaintIstanbul.

2023 09/23

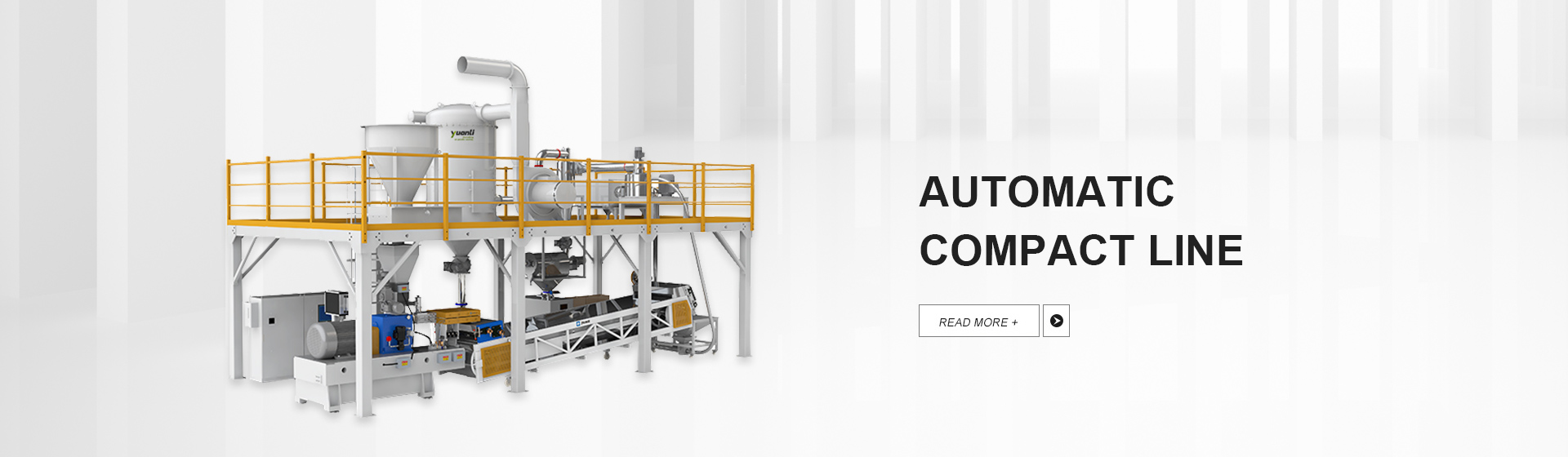

- Yuanli Family have a nice trip on 16th-17th wonderful SepetemberStart a wonderful journey, enjoy the time of September, and leave unforgettable memories! Yuanli intruoduce Yuanli was established in 1988, specializing in the Production of electrostatic powder coating equipment with professional awareness and rigorous attitude. Relaying on our eminent technology, advanced quality and lean management, we provide services from workshop layout designing, equipment installation, know-how training, technical support, formulation consultancy until powder coating production completes. Our equipment has been exported to Italy, Turkey, India, Vietnam, Poland,Philippines, Iran, Egypt, Saudi Arab, Singapore, Russia, Thailand, USA & several other European countries (through middle company in Italy) etc. Adhering to our business strategy" striving for excellence", Yuanli has accomplished an R&D revolution with stable quality and high efficient patent products, and will consistently make great effort to achieve the maximum customer satisfaction. As leading manufacturing in powder coating field,we have 30 years rich experience.Our R&D team developed OPTIMIZED SERIES" which comes in two type(E type & D type) and NEWTEC SERIES.Including lab production line,Premixer,extruder,cooling belt and mill system. The products can satisfy the capacity from 10kg/h-1000kg/h. We supply NEW series of raw material with strong support in Know-how,Technology,Turnkey Project and Formulation. Product Series: NEWFILL:Precipitated barium sulfate;Natural barium sulfate NEWPOX:Epoxy resin NEWPOL:Polyester resins(Pure,hybrid and PU) NEWADD:TGIC,Benzoin,Flow agent,Tio2,Matting Hardener. We arrived at the spot "CHINESE COURTYARD" BARBECUE TIME, ENJOTY DINNER ENJOY THE SCENERY Thank you for Yuanli Family, Let us together go to a better future!

2023 09/16

Email to this supplier